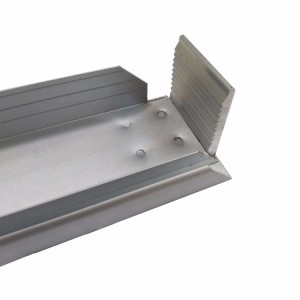

Solar ribhoni cell connector bhazi bar waya

Tsanangudzo

Solar Tabbing waya Mechanical Property:

1. Elongation: E-Soft>=20% U-Soft>=15%

2. Kusimba simba:>=170MPa

3. Side camber: L<=7mm/1000mm

4. Kunyungudika kwerata: 180~230°C

Electric Resistivity of Copper:

TU1<=0.0618 Ω·mm2/m; T2<=0.01724 Ω·mm2/m

Core Copper yeTU1 Off-Cu kana ETP1:

1. Copper Kuchena > = 99.97%, Oxygen<=10ppm

2. Kusagadzikana: ρ20<=0.017241 Ω·mm2/m

Electric Resistivity yeRibhoni:

(2.1~2.5)X10-2 Ω·mm2/m

Plated Ukobvu:

1) Hand-Soldering: 0.02-0.03mm padivi

2) Machine-Soldering: 0.01-0.02mm padivi

Kuumbwa kwePlated Material:

1) Kutungamira akatevedzana zvigadzirwa:

A.Sn 60%, Pb 40%

B.Sn 63%, Pb 37%

C.Sn 62%, Pb 36%, Ag 2%

D. Sn 60%, Pb 39.5%, Ag 0.5%

2) Lead-yemahara akatevedzana zvigadzirwa:

A. Sn 96.5%, Ag 3.5%(Bi)

B. Sn 97%, Ag 3% zvichingodaro

Nezve Tabbing Ribhoni & Bhazi bar Ribhoni

PV ribhoni inoumbwa neMhangura uye yekubikira alloys, uye yakakamurwa kuita Tabbing Ribbon uye Bhazi bar ribhoni.

1. Kubata Ribhoni

Tabbing Ribhoni inowanzobatanidza mativi akanaka uye asina kunaka emaseru munhevedzano.

2. Bhazi Ribhoni

Bhazi bhari Ribhoni inonangana nesero tambo mujunction bhokisi uye chiteshi magetsi emagetsi.

Nezve Coating Alloy:

Mhando yekuputira inotarirwa nekugadzirwa kwemutengi uye kudiwa. Iyo yakakamurwa kuita lead uye yakafa-isina coating. Parizvino iyo inotungamira yekupfekedza mhando inoshandiswa zvakanyanya, asi mune ramangwana ichagadziridzwa kune lead-isina coating mhando.

specifications

| SIZE(mm) | UKObvu(mm) | Mhangura NYAYA | KUSHINGIRIRA | ||

| WXT | Base Copper | Jachi padivi | Upamhi | Ukobvu | |

| 0.6x0.12 | 0.0500 | 0.0150 | TU1 | +/-0.05 | +/-0.015 |

| 0.8x0.08 | 0.0500 | 0.0150 | TU1 | ||

| 0.8x0.10 | 0.0500 | 0.0250 | TU1 | ||

| 1.0x0.08 | 0.0500 | 0.0150 | TU1 | +/-0.05 | +/-0.015 |

| 1.0x0.10 | 0.0500 | 0.0250 | TU1 | ||

| 1.5x0.15 | 0.1000 | 0.0250 | TU1 | +/-0.05 | +/-0.015 |

| 1.5x0.20 | 0.1500 | 0.0250 | TU1 | ||

| 1.6x0.15 | 0.1000 | 0.0250 | TU1 | +/-0.05 | +/-0.015 |

| 1.6x0.18 | 0.1250 | 0.0275 | TU1 | ||

| 1.6x0.20 | 0.1500 | 0.0250 | TU1 | ||

| 1.8x0.15 | 0.1000 | 0.0250 | TU1 | +/-0.05 | +/-0.015 |

| 1.8x0.16 | 0.1100 | 0.0250 | TU1 | ||

| 1.8x0.18 | 0.1250 | 0.0275 | TU1 | ||

| 1.8x0.20 | 0.1500 | 0.0250 | TU1 | ||

| 2.0x0.13 | 0.0800 | 0.0250 | TU1 | +/-0.05 | +/-0.015 |

| 2.0x0.15 | 0.1000 | 0.0250 | TU1 | ||

| 2.0x0.16 | 0.1100 | 0.0250 | TU1 | ||

| 2.0x0.18 | 0.1250 | 0.0275 | TU1 | ||

| 2.0x0.20 | 0.1500 | 0.0250 | TU1 | ||

Technology Process

1,Kugadzira waya dzakatenderera kuti dzipere waya kuburikidza nekudhirowa nekukunguruka

2,Kubata kupisa

3,Hot-dip tinning

4,Kunyatso spooling

Copper base ndiyo yeokisijeni isina mitsetse yemhangura inobatiswa neakanyanya-chaiyo rolling michina inotengeswa kubva kuGermany.

Iyo yakapfava uye haina bur edge, iyo yakapfava kuomarara inogona kugadziriswa nezvinodiwa nevatengi.

Iine chaiyo formula tekinoroji, iyo tin alloy jasi inogadzirwa nenyanzvi inopisa-kunyudza tinning michina inounzwa kubva kuJapan. Coat suface inopenya uye kunyange, ine inogoneka kuita uye yakasimba antioxidant iyo inobatsira kupinza goho rewelding. Ukobvu hwayo hunogona kugadziriswa nezvinodiwa nevatengi.

Ribhoni inogona kugadzirwa kurongeka zvinoenderana nesolar module uye chiyero chayo

Product Display